Ինչպես պահպանել ճկուն հարթ խողովակը երկարաժամկետ օգտագործման համար

Հարթ խողովակի սպասարկման և երկարակեցության հիմնարար ուղեցույց

Արդյունավետ հեղուկի տեղափոխման լուծումների դեպքում հարթ խողովակը տարբեր արդյունաբերություններում անհրաժեշտ գործիք է դարձել: Այս տարբերատեսակ խողովակները առաջարկում են բացառիկ կեցվածք և պահպանման առավելություններ, սակայն դրանց երկարակեցությունը կախված է ճիշտ սպասարկումից և խնամքից: Ձեր հարթ խողովակի սպասարկման մասին գիտելիքը կարող է երկարաձգել դրա ծառայության ժամկետը, ապահովել օպտիմալ արդյունավետություն և երկարաժամկետ պաշտպանել ձեր ներդրումը:

Հատակի խողովակների մասնագիտական սպասարկումը ներառում է ոչ միայն պարզ մաքրում և պահպանում: Այն պահանջում է համապարփակ մոտեցում, որը հաշվի է առնում նյութերի բնութագրերը, օգտագործման ձևերը և շրջակա միջավայրի գործոնները: Այս ուղեցույցը կուսումնասիրի հատակի խողովակների սպասարկման հիմնական ասպեկտները՝ օգնելով ձեզ առավելագույնի հասցնել դիմացկունությունը՝ միաժամանակ պահպանելով առավելագույն արդյունավետությունը դրա ողջ ծառայության ժամկետի ընթացքում:

Լեցող ստվար խողովակի կառուցվածքի և հատկությունների հասկացություն

Նյութի կազմություն և դիզայնի առանձնահատկություններ

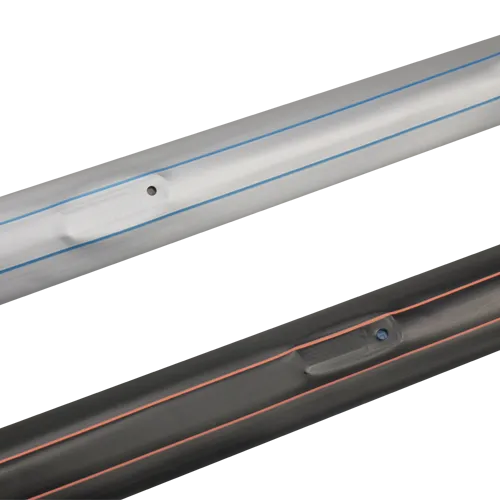

Լեցող ստվար խողովակը ստեղծված է բարձր ամրության սինթետիկ նյութերի բազմաշերտ կառուցվածքով, սովորաբար ներառում է պոլիէսթեր ամրացված թիկնոց և TPU կամ PVC պատյան: Այս կառուցվածքը թույլ է տալիս խողովակին պահպանել իր կառուցվածքային ամբողջականությունը՝ միաժամանակ պահպանելով բավարար ճկունություն՝ հնարավոր դարձնելով այն սեղմվել մինչև հարթ վիճակ օգտագործումից հետո: Արտաքին թիկնոցը ապահովում է մաշվածության դիմադրություն և պաշտպանություն, իսկ ներքին պատյանը ապահովում է հեղուկի հարթ հոսք և քիմիական դիմադրություն:

Ժամանակակից հարթ պոլիուրեթան խողովակները ներառում են արդյունավետ ավելացուցիչ հատկություններ, ինչպիսիք են ՈՒՖ պաշտպանությունը, հակամիկրոբայական միջոցները և հատուկ ծածկույթներ, որոնք մեծացնում են նրա տևողականությունը: Այս բաղադրիչների հասկանալը օգնում է իրականացնել համապատասխան սպասարկման ընթացակարգեր, որոնք պաշտպանում են յուրաքանչյուր շերտ և պահպանում խողովակի ընդհանուր գործառույթները:

Գործառության հատկանիշներ և սահմանափակումներ

Յուրաքանչյուր հարթ խողովակ ունի հստակ շահագործման պարամետրեր՝ ներառյալ առավելագույն աշխատանքային ճնշում, ջերմաստիճանային տիրույթ և քիմիական համատեղելիություն: Այս սահմանափակումները ուղղակիորեն ազդում են սպասարկման պահանջների և գործընթացների վրա: Այս պարամետրերի պարբերական գնահատումն ապահովում է, որ խողովակը աշխատում է իր նախատեսված սպեցիֆիկացիաների սահմաններում, կանխելով прежդևրեմեննույ մաշվածությունը և հնարավոր ձախողումը:

Կատարողականի հսկումը պետք է ներառի ճնշման պահպանումը, ճկունությունը և նյութի վատթարացման ազդանշանները կանոնավոր ստուգումներ: Ձեր լեռնահարթ խողովակի հստակ հնարավորությունների մասին տեղեկացված լինելը օգնում է մշակել թիրախային սպասարկման график, որը հաշվի է առնում հնարավոր թույլ կետերը՝ նախքան դրանք խնդրահարույց դառնալը:

Օրական սպասարկում և ստուգման կանոններ

Օգտագործումից առաջ ստուգման ընթադարձություններ

Յուրաքանչյուր օգտագործումից առաջ հիմնավոր տեսողական ստուգում կատարեք ձեր հարթ խողովակի վերաբերյալ: Ուշադիր նայեք արտաքին վնասվածքների նշաններին՝ ինչպիսիք են կտրվածքները, մաշվածքները կամ դեֆորմացիան: Ստուգեք միացման կետերն ու վերջամասերի ամրացումը՝ ապահովելով դրանց ամրությունն ու ճիշտ տեղադրումը: Այս նախնական ստուգումը կարող է կանխել շահագործման խնդիրներ և նախազգուշացնել հնարավոր խնդիրներ, մինչև դրանք բարդանան:

Особое внимание уделите зонам, которые испытывают наибольшее напряжение во время использования, таким как точки изгиба и зоны соединения. Фиксируйте все наблюдения и ведите журнал результатов осмотра, чтобы отслеживать состояние шланга с течением времени.

Օգտագործումից հետո մաքրում և պահպանում

Յուրաքանչյուր օգտագործումից հետո հարթ խողովակի ճիշտ մաքրումը կարևոր է դրա վիճակը պահպանելու համար: Խողովակը լվացեք մաքուր ջրով՝ հեռացնելով մնացորդային նյութերը, հատկապես երբ տեղափոխվում են ջրից բացի այլ նյութեր: Օգտագործեք խողովակի նյութի հետ համատեղելի մաքրման լուծույթներ՝ կախված տեղափոխվող նյութի տեսակից:

Ճիշտ չորացման և պահպանման կանոնները նույնպես կարևոր են: Պահեք խողովակը ամբողջությամբ չորանալու և օդով չորացման համար նախքան պահեստավորումը: Պահեք խողովակը մաքուր, չոր միջավայրում՝ հեռու ուղիղ արևի լույսից և չափազանց բարձր կամ ցածր ջերմաստիճաններից: Ճիշտ գալարման տեխնիկան կանխում է ծալքերի առաջացումը և պահպանում խողովակի բնական ճկունությունը:

Երկարաժամկետ պահպանման ռազմավարություններ

Պահպանման պարագայումների գրաֆիկ

Իրականացրեք կառուցված սպասարկման գրաֆիկ, որը ներառում է հիմնական մաքրում, համապարփակ զննումներ և ճնշման փորձարկում: Այս գործողությունները ծրագրավորեք ըստ օգտագործման հաճախադեպության, շահագործման պայմանների և արտադրողի խորհուրդների: Լավ պլանավորված սպասարկման ծրագիրը օգնում է վաղ փուլում նույնականացնել հնարավոր խնդիրները և երկարաձգել հարթ պարանի ծառայողական վայրը:

Շարունակաբար փաստաթղթավորեք բոլոր սպասարկման գործողությունները՝ ներառյալ ամսաթվերը, կատարված գործընթացները, որևէ ներկայացումներ կամ փոխարինումներ: Այս փաստաթղթավորումը ստեղծում է արժեքավոր պատմություն, որը կարող է օգնել կանխատեսել սպասարկման կարիքները և ժամանակի ընթացքում օպտիմալացնել սպասարկման գրաֆիկը:

Շրջակա միջավայրի պաշտպանության միջոցառումներ

Պաշտպանեք ձեր հարթ պարանը այն շրջակա միջավայրի գործոններից, որոնք կարող են արագացնել մաշվածությունը: Օգտագործեք պաշտպանիչ ծածկեր կամ պահեստավորման լուծումներ, որոնք պաշտպանում են պարանը ՈՒՖ ճառագայթումից, չափազանց բարձր կամ ցածր ջերմաստիճաններից և ծայրահեղ եղանակային պայմաններից: Հաշվի առեք սեզոնային պահեստավորման պահանջները և համապատասխանաբար կարգավորեք սպասարկման գործընթացները:

Հսկեք պահեստային հարթակները՝ հնարավոր վտանգների, ինչպիսիք են սուր առարկաները, քիմիական նյութերի ազդեցությունը կամ վնասատուների ակտիվությունը: Իրականացրեք խողովակը այդ շրջակա միջավայրի վտանգներից պաշտպանելու համապատասխան միջոցառումներ՝ պահպանելով ճիշտ վենտիլյացիան և ջերմաստիճանի վերահսկողությունը:

Խափանումների հայտնաբերման և վերանորոգման հրահանգներ

Ծանոթ խնդիրներ և լուծումներ

Լուծեք փոքր խնդիրները անմիջապես՝ ավելի լուրջ խնդիրներ կանխելու համար: Լայն խողովակների հետ կապված հաճախ հանդիպող խնդիրներից են մակերեսային մաշվածությունը, միացումների խնդիրները և ճկունության կորուստը: Մշակեք այդ խնդիրները հայտնաբերելու և լուծելու համակարգային մոտեցում՝ հետևելով արտադրողի հրահանգներին վերանորոգումների և մասերի փոխարինման հարցերում:

Պահեք անհրաժեշտ վերանորոգման պիտույքներ և մասեր արագ վերանորոգումներ կատարելու համար: Ուսուցանեք սպասարկման անձնակազմին ճիշտ վերանորոգման մեթոդներին և ուսուցանեք, թե երբ պետք է դիմել մասնագետներին՝ ավելի բարդ խնդիրներ լուծելու համար:

Մասնագիտացված սպասարկման ծառայություններ

Ընդգրկեք ոqualifiedանակավոր սպասարկման մատակարարների հետ հարաբերություններ հատուկ նշանակության պահպանման և վերանորոգման համար: Մասնագիտական սպասարկումը կարող է ներառել ճնշման փորձարկում, միացումների փոխարինում կամ խողովակի ամբողջական վերականգնում: Պարբերական մասնագիտական ստուգումները կարող են հայտնաբերել հնարավոր խնդիրներ, որոնք կարող են բաց մնալ սովորական պահպանման ընթացքում:

Հաշվի առեք մասնագիտական սպասարկման և փոխարինման ծախսերի հարաբերակցությունը՝ զգալի մաշվածության կամ վնասվածքների դեպքում: Երբեմն մասնագիտական սպասարկման մեջ ներդրումները կարող են զգալիորեն երկարաձգել խողովակի ծառայողական կյանքը և երկարժամկետ առումով ավելի տնտեսապես շահավետ լինել:

Հաճախ տրվող հարցեր

Որքա՞ն հաճախ պետք է ստուգեմ իմ հարթ խողովակը:

Ստուգումները պետք է կատարվեն յուրաքանչյուր օգտագործումից առաջ և հետո, իսկ ավելի մանրամասն ստուգումները՝ ամսեկան մեկ անգամ: Բարձր օգտագործման պայմաններում կարող է անհրաժեշտ լինել ավելի հաճախադեպ ստուգում: Կազմեք ստուգման ցուցակ, որը ներառի տեսողական ստուգում, ճնշման փորձարկում և միացումների գնահատում:

Ո՞ր մաքրող միջոցներն են անվտանգ օգտագործել հարթ խողովակների համար:

Օգտագործեք ձեր խողովակի նյութի համատեղելի մեղմ, ոչ սաղմանի մաքրող լուծույթներ: Խուսափեք կորոզիվ քիմիկատներից, որոնք կարող են վնասել խողովակի նյութը: Միշտ լավ բաց լվացեք մաքուր ջրով մաքրելուց հետո և թողեք ամբողջությամբ չորանալ պահեստավորման առաջ:

Ինչպե՞ս կարող եմ առավելագույնի հասցնել հարթ պահվող խողովակի պահման ժամկետը:

Պահեք խողովակը մաքուր, չոր միջավայրում՝ հեռու ուղղակի արևի լույսից և չափազանց բարձր ջերմաստիճաններից: Օգտագործեք ճիշտ գալարման մեթոդներ, խուսափեք սուր ծռումներից և համոզվեք, որ ապահովված է բավարար օդափոխություն: Հաշվի առեք հատուկ պահման լուծումների օգտագործումը, որոնք նախատեսված են հարթ պահվող խողովակների համար՝ դրանց ձևը պահպանելու և վնասվածքներից պաշտպանելու համար: